To decrease the overall manufacturing costs of your product, you need to start with a detailed understanding of the core cost drivers. Building from this foundation, you can then determine what cost reductions levers make the most sense to pull as a function of where you are in the New Product Introduction (NPI) and manufacturing process.

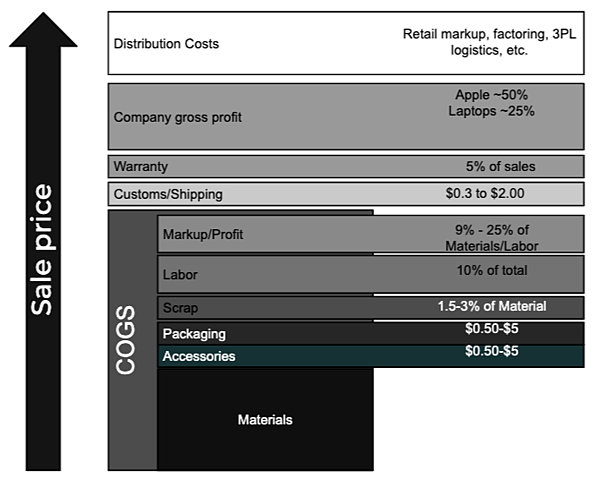

To be able to model your financials, it is critical to understand the true Cost of Goods Sold (COGS), which is how much you pay the factory for each unit. On top of this cost, you also need to understand the fixed costs, which includes items such as tooling, stencils, test fixtures, Non-Recurring Engineering (NRE) (i.e. engineering services), pre-production samples, certifications and regulatory affairs, and more.

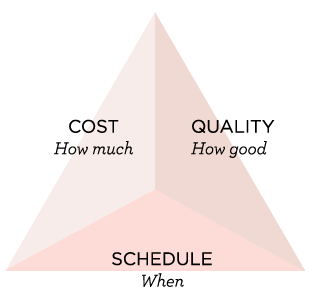

Many companies assume they can simply sum up the Bill of Materials (BOM) cost and arrive at the Cost of Goods Sold (COGS). This approach is flawed and will result in a misleadingly low COGS which can catastrophically impact a business. When calculating COGS, it’s important to include labor, scrap, factory overhead and profit as well. For large items, logistics (i.e. shipping) can also add up, especially if the products need to be air shipped to meet a schedule (including these logistics costs results in the “landed” cost).

Fixed Costs refer to one-time expenses that will be incurred to manufacture and sell a product as represented by the diagram above.

These costs do not increase in a linear relationship to volume.

Once the COGS is understood, the hidden killer becomes the payment terms with both the factory and the customer.

By negotiating better terms with both parties, it is possible to significantly reduce the working capital requirements. This means your company will have less cash tied up in manufacturing and in turn, be significantly better positioned to grow as well as protect the shareholder equity.

Component terms

When you pay your supplier

CM terms

When you pay your Contract Manufacturer

Customer Terms

When your customers pay you

Shipping

When/How your product gets to your distributor

Gross margin represents the amount of money you retain after manufacturing that can be put towards marketing, R&D and profit.

Understanding your manufacturing costs will help you be successful. Know everything from Cost of Goods Sold to Gross Margin to better negotiate terms with your supplier, CM and end customer.

“I'm glad we went through Dragon. They really helped with understanding all the costs associated with this product domestically and overseas. If we break MOQs for overseas manufacturing we will definitely pursue with Dragon's RFQ and PM services.”