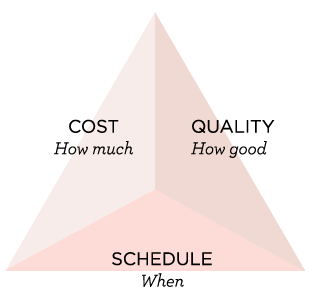

While arguably the most critical aspect of your manufacturing planning, Quality often comes as an afterthought to Cost and Schedule.

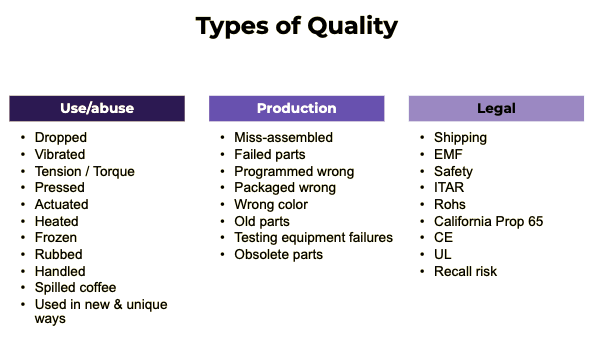

Having a product recalled due to a safety problem can destroy a company's brand and irreparably ruin consumer trust. Many companies leave quality to the very end. It is very hard to test quality into a product after the design is tooled and the component are ordered - much better to design quality in from the start.

As a result, companies are left scrambling to fix issues that are identified later in New Product Introduction (NPI) process , which can be quite costly, especially if tools need to be modified, long lead-time components need to be ordered, or inventory needs to be reworked. Worse yet, if the product has already been shipped and it has taken a while to identify an issue, there could be a high volume of defective product in the field.

Designing a comprehensive approach to quality and testing takes time, which will impact the schedule. Many companies fail to accurately plan this into the schedule and put the product at risk for either missing a key shipping milestone or being forced to ship with incomplete knowledge of the product. There is always some uncertainty, as it's never feasible to test every possible failure mode while meeting the cost and schedule targets. Teams must be comfortable and proficient making correct decisions with limited data. Still, building in ample time to test your product will pay dividends in the long run.

There are several major misconceptions that can lead to quality failures in the field. Learn what you need to know before talking to your CM.

Learn MoreUnderstand the importance of manufacturing quality by knowing the types of quality to look out for, having a quality plan, and knowing how to communicate quality with your CM.

Learn More“As a team of first time founders, the only thing we knew going in was that 'hardware is hard', so we relied on the Dragon team to help us with our quality plan, prepare for our first site visit, and oversee critical initial production runs. Their quality plan helped our team institutionalize quality as a fundamental metric of manufacturing and understand how to measure and manage to our specifications”