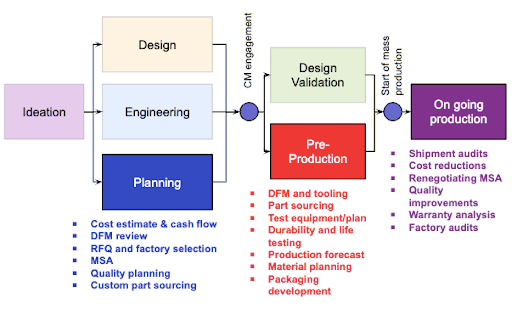

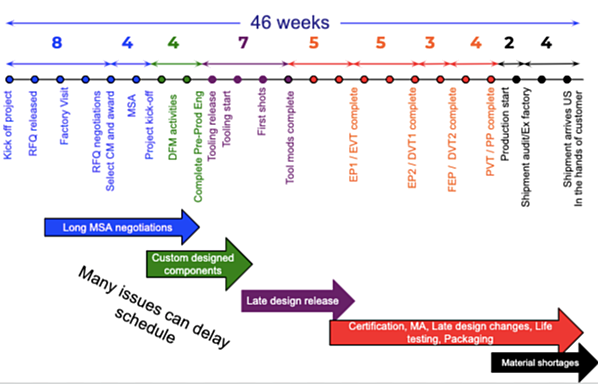

From long-lead time components to testing and certifications, understand the many factors and challenges that will affect your manufacturing schedule.

Being late to market can be devastating, as the company will miss critical revenue and need to wait another year before the sales opportunity comes back. In consumer electronics, the product sales cycle is often driven by the winter holiday season sales. Many companies make the majority of their revenue for the year in tied to revenue goals for a fixed date. In this time, they will need to cover the financial burn of the team, and are more susceptible to competitive threats after they have revealed their product to the market.

In high production volumes, as opposed to lower prototyping quantities, many components have lead-times. For some electrical components (i.e. MLCCs), these lead-times can be over a year! For fabricated parts, such as injection molding tooling, it often takes up to 8 weeks to make the tool before the plastic part is available. If a company has not factored in these lead times, they will either miss the sales opportunity or erode their margins paying for expedited service (air shipping, etc.).

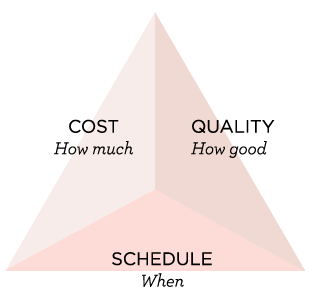

When creating a production schedule, there are many things to keep top of mind so you don’t miss your deadline.

Manufacturing deadlines can make or break your company. If you miss your holiday schedule, your companies’ expected revenue can impact your whole business.

“We could not have put together an RFQ as fast as we did without Dragon's software that guided us every step of the way. It made the whole process of getting ready for factories painless.”

“With Dragon Innovation's help we have been able to go very fast while maintaining the assurance that our decisions are vetted by deep, hard to find experience in manufacturing.”

“As soon as we finished our first session, we had a list of detailed molding issues that saved us weeks of design time.”