The term “prototype” is very broad. It encompasses everything from a 5-minute model thrown together with masking tape and cardboard to one that took weeks to make with injection molded parts and custom-designed circuit boards. Regardless of the kind of prototype, the purpose of prototyping is to learn something new. You can learn a lot with CAD but there’s nothing like holding a physical sample in your hand. CAD can never tell you what something feels like in your hand or how big it feels in a room.

Let's break down the way to think about prototyping into 3 high level ideas:

1. Prototype Early and Often

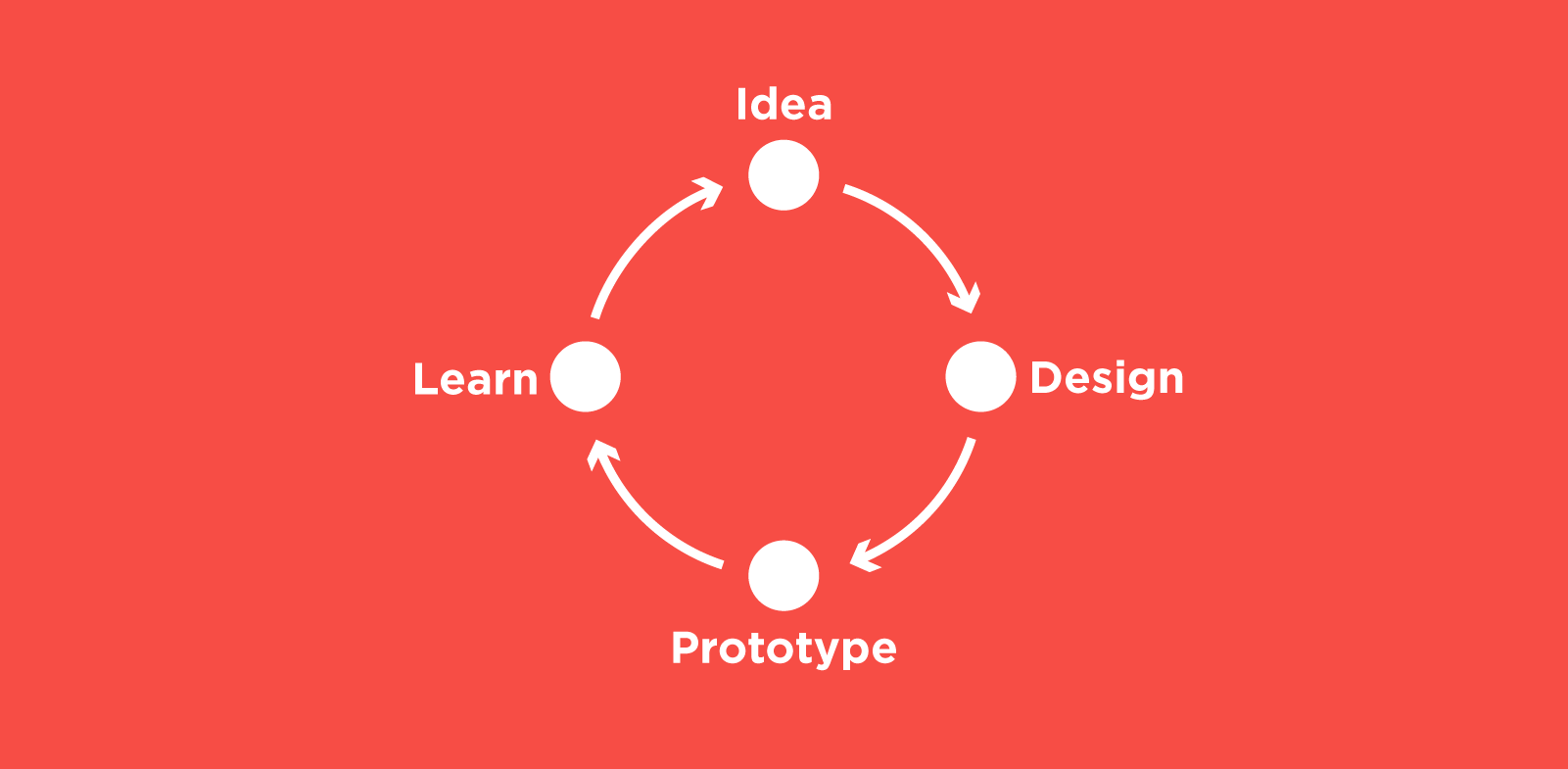

I hear a lot of people talk about prototyping as a stage that comes after the design is pretty much done. This robs you of a lot of the benefits that prototyping can provide. Instead, I think of prototyping as a tool, like CAD, that I use throughout the design phase. It’s part of a very important feedback loop: idea, design, prototype, learn, improved idea… Early in your design phase you might tape together a few pieces of cardboard to get a sense of how big your product feels in a room. Later on you might make some machined prototypes to test how strong different shapes and materials are. And before you go into production you should make a prototype that is as close, if not exact, to the look and function as you possibly can. Early prototypes are also a great way to do user testing and to validate that you are making a product that people are willing to buy!

(More on that in another post.

I was talking to the team at Dragon Innovation about this and he said something that really sums this up: “Prototype is not a noun, it’s a verb.”

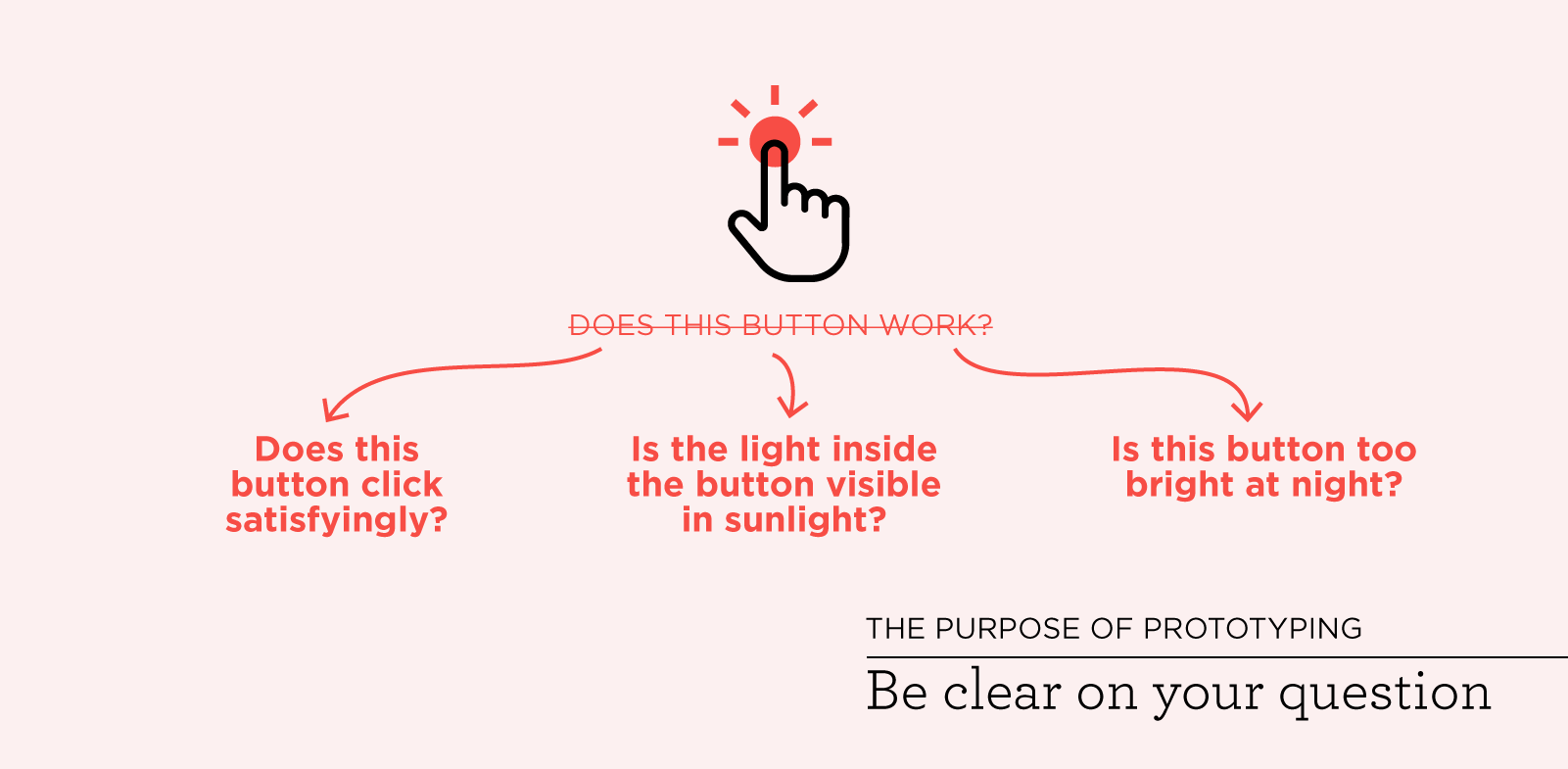

2. Be Clear on Your Question

To make my prototypes as productive as possible I always make sure that I am clear on what question I’m trying to answer with the prototype. I don’t want to make a prototype just to a check box. I also don’t want to make a prototype based on a question that isn’t well specified, and then find that I can’t get any useful information that moves my project forward. If you don’t have a clear question, try breaking the problem down into simpler parts that are easier to test. Not, “Does this button work?” but “Does the button click satisfyingly” or “Is the light inside the button visible in sunlight or too bright at night”, etc. This leads nicely into my third point.

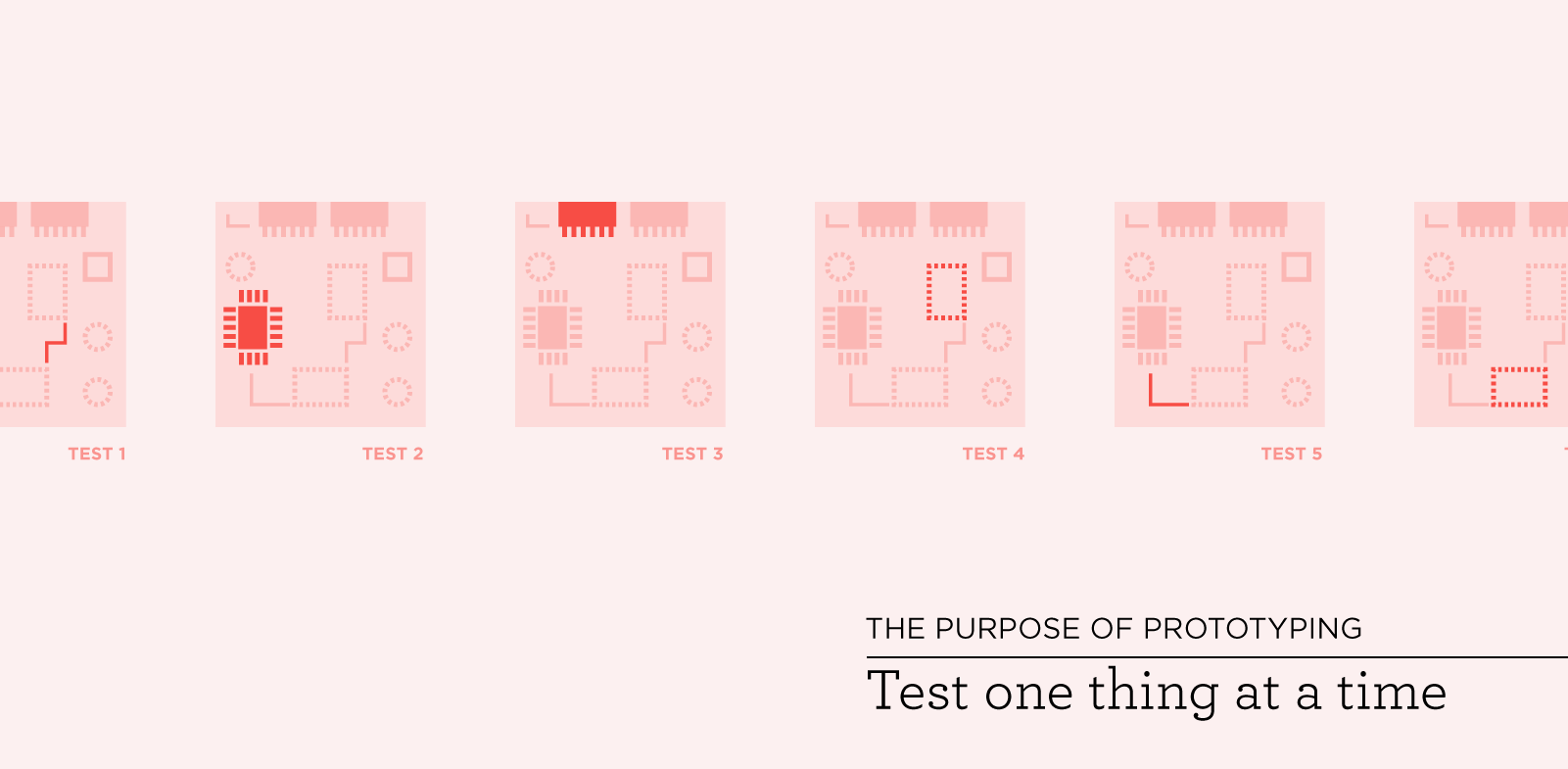

3. Test One Thing at a Time

It’s tempting to think that building prototypes that test many things at once will be “more efficient,” but this is a dangerous path. The more complex a prototype is, the longer it takes to build. As a result, the slowest feature to make delays answers on all your other features. Worse yet if one feature fails, then you might not even be able to test the others. I have made this mistake many times before, but probably the worst was when I was designing an electrical connector for very sensitive analogue signals. There are two essential functions to any electrical connector; the actual electrical connection and the mechanical connection that ensures the two parts stay together. I was overly confident in the design so I was building both of them at the same time at great expense. When we put the two parts together nothing worked! We made a number of adjustments but never got it work well enough. We ended up scrapping the design and going a completely different way. Two years later an intern started playing around with the prototypes and go it to work in a few weeks. The electrical connection was excellent, he just replaced the mechanical connection.

I hope that these three ideas will help you get started on your own prototyping. I will share more ideas and more examples in the coming posts. I hope that you can learn from my mistakes so that you can make new ones!

A brief introduction:

I'm James Berg. I like making things, I do it professionally and I do it in my free time. Currently I work at Athos, a smart fitness garment company; previously I have worked in consumer electronics and solar power. In my free time I make things ranging from modular shelving to displays that tell me when the next bus is stopping near my house to gingerbread carousels. You can follow me on Twitter here: https://twitter.com/mudmucker